Getting Started

Danger: These boards can get extremely HOT

Please handle these boards with the utmost caution. Users can easily burn themselves; especially, when the board outputs anything over 2A.

Note

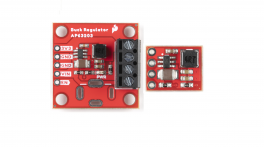

The SparkFun Buck Regulator Breakout - 5V (AP63357DV) and BabyBuck Regulator Breakout - 5V (AP63357DV) have similar features to our previous 3.3V buck regulators (AP63203).

Introduction

These boards feature the AP63357 from Diodes Inc., a 3.5A synchronous buck converter with a wide input voltage range of 3.8V to 32V. The fully integrated 74mΩ high-side power MOSFET/40m low-side power MOSFET provide a high-efficiency step-down DC/DC conversion. The boards are configured to provide a regulated 5V output and feature a high-voltage EN (enable) control pin that is rated up to 32V. The boards also include 0.1" spaced PTH pins to connect the input and output power and a copper pad is provided to attach a heat sink to the bottom of the board; to dissipate excess heat.

-

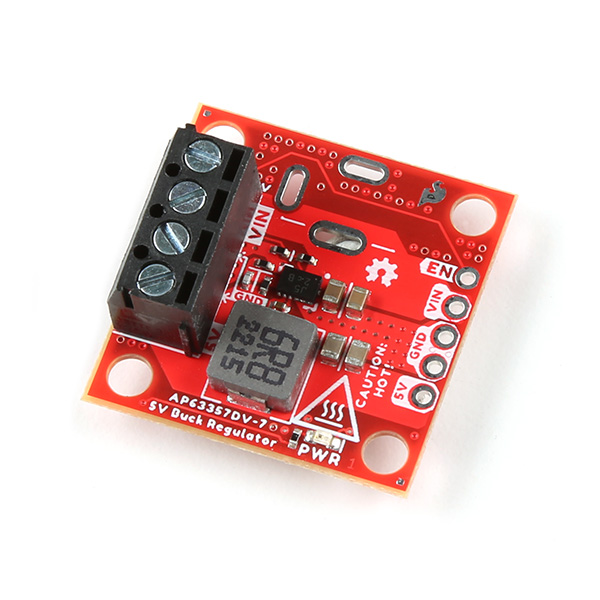

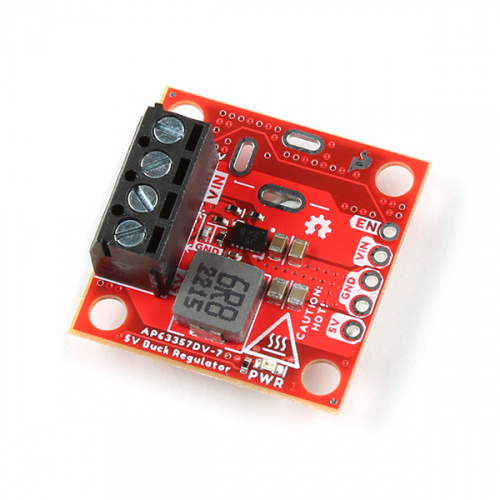

5V Buck Regulator

SKU: COM-21255

The Buck regulator breakout board, has additional options for connecting input and output power. There is a pre-assembled screw terminal for a non-permanent connection and the option to solder on a barrel jack for an external power supply. The board also includes and red, power indication LED for when the power output is enabled.

Purchase from SparkFun

Purchase from SparkFun

-

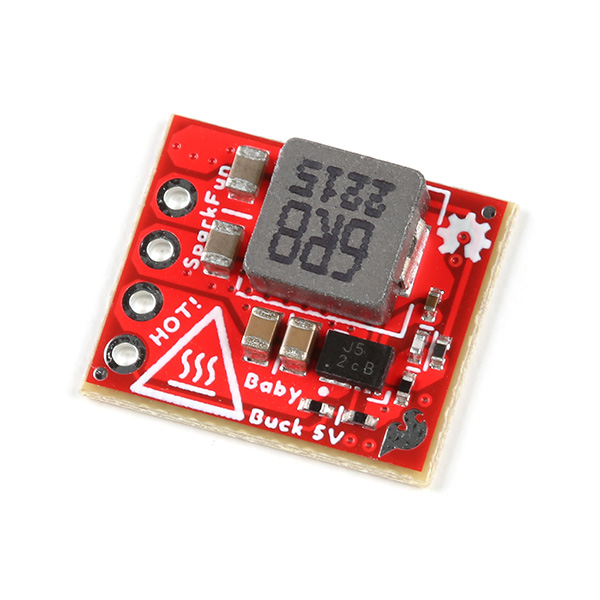

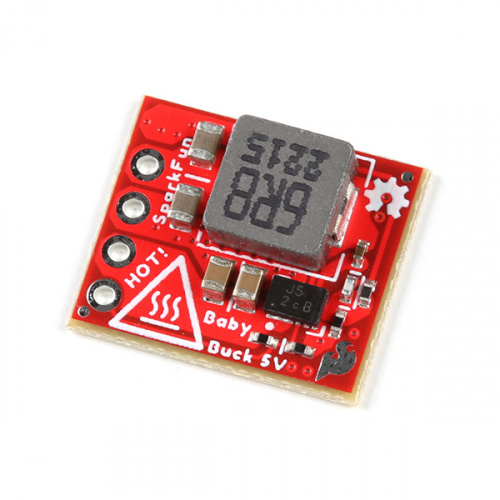

5V BabyBuck Regulator

SKU: COM-21256

Unlike its sibling, the BabyBuck is a minimalistic board that sacrifices the connection options for space. Don't worry, though, because the PTH pins are still available to connect the input and output power. All of this snuggled up in a low-profile, .63" x .52" board.

Purchase from SparkFun

Purchase from SparkFun

Required Materials

To get started, users will need a few items. Now some users may already have a few of these items, feel free to modify your cart accordingly.

- SparkFun Buck Regulator Breakout - 5V (AP63357DV)

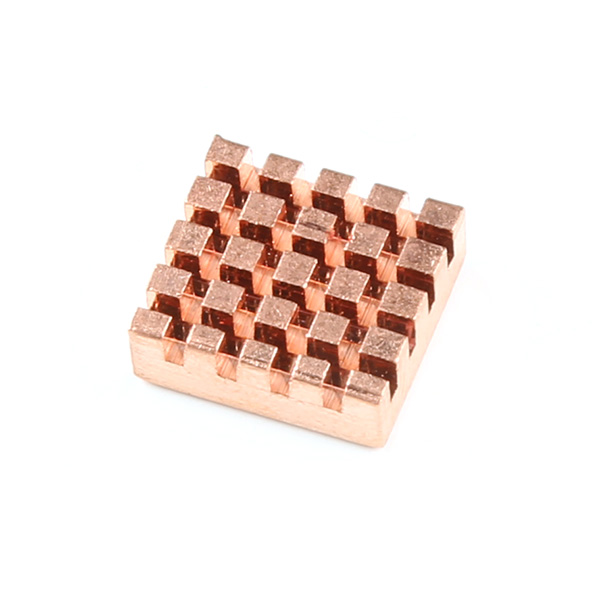

- Heat Sink - Used to help dissipate excess heat

- Thermal Tape - To attach a heat sink to the board

- Power Supply

-

Soldering Tools (1)

- Check out the beginner tool kit below; otherwise, click here for a full selection of our available soldering tools.

-

Hookup Wire - May be used to connect the external power or power output

- Headers - May be used to connect the external power or power output

- DC Barrel Jack Adapter - (Optional - Not necessary for the BabyBuck Regulator)

- Small Flathead Screw Driver - (Optional - Not necessary for the BabyBuck Regulator)

SparkFun BabyBuck Regulator Breakout - 5V (AP63357DV)COM-21256 |

SparkFun Buck Regulator Breakout - 5V (AP63357DV)COM-21255 |

Heatsink - 13.20 x 12.10 mm (Copper)PRT-18704 |

Thermal Tape 4x4" SquarePRT-17054 |

SparkFun Beginner Tool KitTOL-14681 |

Hook-Up Wire - Assortment (Solid Core, 22 AWG)PRT-11367 |

Break Away Headers - StraightPRT-00116 |

DC Barrel Power Jack/ConnectorPRT-00119 |

Pocket Screwdriver SetTOL-12891 |

New to soldering?

Check out our Through-Hole Soldering Tutorial for a quick introduction!

Jumper Modification

New to jumper pads?

Check out our Jumper Pads and PCB Traces Tutorial for a quick introduction!

To modify the jumper, users will need soldering equipment and/or a hobby knife.

Solder Lead Free - 100-gram SpoolTOL-09325 |

Weller WLC100 Soldering StationTOL-14228 |

Chip Quik No-Clean Flux Pen - 10mLTOL-14579 |

Hobby KnifeTOL-09200 |

Suggested Reading

Below, are a few tutorials that may help users familiarize themselves with various aspects of this product:

Hardware Overview

Danger: These boards can get extremely HOT

Please handle these boards with the utmost caution. Users can easily burn themselves when the board outputs anything over 2A.

Board Dimensions

The board dimensions are illustrated in the drawing below; the listed measurements are in inches.

Board dimensions (PDF) for the 5V buck regulator breakouts (AP63357), in inches.

Need more measurements?

For more information about the board's dimensions, users can download the eagle files for the board. These files can be opened in Eagle and additional measurements can be made with the dimensions tool.

Eagle - Free Download!

Eagle is a CAD program for electronics that is free to use for hobbyists and students. However, it does require an account registration to utilize the software.

Dimensions Tool

Dimensions Tool

This video from Autodesk demonstrates how to utilize the dimensions tool in Eagle, to include additional measurements:

Power

Users are provided with PTH to connect their external power supply, the output voltage from the board, and the EN power control pin for the buck regulator. The AP63357 buck regulator has an input voltage range is 3.8V to 32V. However, the boards require a 6V minimum power supply to operate; as it is a step-down DC/DC converter with a 5V output. (i.e. The boards cannot step-up or boost the voltage output.)

The PTH power pins on the 5V Buck Regulator (AP63357DV). |

The PTH power pins on the 5V Baby Buck Regulator (AP63357DV), viewed from the bottom. |

Below, is a general summary of the circuitry on the board:

VIN- Power supply input (6V to 32V)- The undervoltage lockout will engage intermittently if the input voltage is below 6V.

EN- Enables the power output of the board- Has an input voltage range up to 32V

- Must be pulled

HIGHabove 1.18V to enable the power output.

5V- Regulated 5V output (up to 3.5A)GND- The common ground or the 0V reference for the board

Info

For more details, users can reference the schematic and the datasheets of the individual components in the power circuitry.

Limitations - Load Current

- While the IC is rated up to 3.5A, users may experience thermal limitations towards that maximum.

- Users should reasonably expect to be able to place a maximum 3A load on the boards when using a heat sink and active cooling (i.e. fan).

- At the peak load of 3.5A, users will need sufficient cooling to prevent the IC's thermal shutdown

- With a heat sink, we have found users can expect to draw up to 2.5A

- Without a heat sink or active cooling, we recommend users not load the boards with more than 1.5A.

Quiescent Current Draw

Users should expect a maximum quiescent current draw of ~365µA from the board due to the voltage divider for the UVLO. For a lower quiescent current, users can modify the board by removing the voltage divider's resistors.

-

Measured Values

Input Voltage (V) Iq (µA) Iq - Power Enabled (µA) 6 65 196 12 129 209 24 260 290.5 32 330 355 Info

For more information about the measured values for the quiescent current, please refer to this GitHub issue.

-

Danger

Modifying a board to remove the voltage divider, requires advanced soldering skills. Users should not attempt this modification unless it is absolutely, necessary and they are confident in their skills because the board can be permanently damaged.

Alternative Connections

Buck Regulator (only)

The following features are only available on the Buck Regulator and are not available on BabyBuck Regulator.

PTH (slots) are provided for users to add a barrel jack connector to the top or bottom of the board. This provides users with an alternative method to connect a power supply to their board.

Power LED

The red, power (PWR) LED will light up when the switching power output is enabled. (Not available on baby buck regulator board.)

The PWR status LED indicator for the 5V Buck Regulator (AP63357DV).

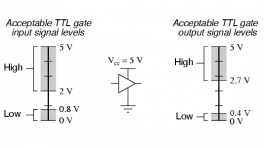

Power Control

There is a high-voltage enable pin (EN) to control the output voltage (i.e. on/off), with a typical threshold voltage of 1.18V and a range up to 32V

- Users should pull the

ENpin high (above 1.18V) to enable the switching power output and pull the pin low to disable it. - As a high-voltage pin, users can also connect the

ENpin toVINto automatically start up the device. - Users can also configure the

ENpin to set the UVLO threshold.

Default Configuration

On our boards, the EN pin is used to set the UVLO threshold. Therefore, the power output from the board is enabled by default.

Enable pin on the 5V Buck Regulator (AP63357DV). |

Enable pin on the 5V Baby Buck Regulator (AP63357DV), viewed from the bottom. |

AP63357

The AP63357 from Diodes Incorporated, is a 3.5A, synchronous buck converter with a wide input voltage range of 3.8V to 32V. The device fully integrates a 74mΩ high-side power MOSFET and a 40mΩ low-side power MOSFET to provide high-efficiency step-down DC-DC conversion. When operating in PFM during light load conditions, the AP63357 can achieve a power efficiency of up to 86% with a 5mA load. Additionally, under a no-load, non-switching condition, the quiescent current is typically 22µA; and when disabled, the device shutdown supply current is only 1μA.

The AP63357 features a high-voltage EN pin that can be directly connected to VIN to automatically start up the device. To prevent output voltage overshoot and inrush current, the AP63357 also has a built-in 4ms soft-start time. Users can also configure the EN pin to set the undervoltage lockout threshold.

Power Efficiency

Users should expect a power efficiency close to the charts presented in Figures 3, 25, and 26 in the datasheet (i.e. 70% with smaller loads and up to 95% with larger loads). While the efficiency varies with the load current and cooling, we didn't see anything below 85% for most of our test cases.

Line and Load Regulation

Users should expect a line and load regulation close to the charts presented in Figures 27 and 28 in the datasheet (i.e. 5.0 ±0.2V). While these vary with the load current and cooling, we didn't see an output voltage below 5V in our tests.

Additionally, we will note that there is some noise in the output voltage, due to the switching of the regulator. While this increases with the load current, for most users it won't be relevant to their use case.

Undervoltage Lockout

An undervoltage lockout is implemented to prevent the IC from insufficient input voltages. The AP63357 device has a UVLO comparator that monitors the input voltage and disables it when the input voltage falls below 3.08V. Some applications may desire higher VIN UVLO threshold voltages than is provided by the default setup. A pull-up current source on the EN pin, along with an external resistive divider (R3 and R4) configure the VIN UVLO threshold voltage, as shown in Figure 37 of section 5 - Adjusting Undervoltage Lockout (UVLO) of the datasheet.

The resistive divider's resistor values are calculated by:

Where:

(1) VON is the rising edge VIN voltage to enable the regulator and is greater than 3.6V

(2) VOFF is the falling edge VIN voltage to disable the regulator and is greater than 3.18V

- Configured at 5.6V

- Configured at 5.18V

Tip

While the undervoltage lockout is configured for 5.6V on the high end, users should provide at least 6V for the input voltage. Based on testing, we found 6V to be a more realistic expectation to avoid an undervoltage lockout from the boards.

Heat Sink Pad

Danger: These boards can get extremely HOT

Please handle these boards with the utmost caution. Users can easily burn themselves when the board outputs anything over 2A.

A platted copper pad is provided on the back of the boards, where users can add a heat sink to dissipate excess heat generated by the AP63357. While the pad size is slightly different between each board, they both can accommodate the copper heatsink in our catalog.

- Buck: 0.5" x 0.6"

- BabyBuck: 0.435" x 0.5"

Heat sink pad on the back of the 5V Buck Regulator (AP63357DV). |

Heat sink pad on the back of the 5V Baby Buck Regulator (AP63357DV). |

Thermal Characteristics

Thermal Shutdown Temperature

The AP63357 has a 170°C (338°F) thermal shutdown temperature.

The thermal limitations of the board will dictate the maximum load current our boards can provide. Below is a chart of some testing we have performed using the full-size, 5V Baby Buck Regulator with a heat sink attached to the back of the board.

Thermal characteristics for the 5V Baby Buck Regulator with a heat sink.

Info

For more information on the thermal characteristics of the AP63357, please refer to the datasheet.

Thermal Limitations on Load Current

- Without a heat sink or active cooling, we recommend users not load the boards with more than 1.5A.

- With a heat sink, we have found users can expect to draw up to 2.5A

- While the IC is rated up to 3.5A, users may experience thermal limitations towards that maximum.

- Users should reasonably expect to be able to place a maximum 3A load on the boards when using a heat sink and active cooling (i.e. fan).

- At the peak load of 3.5A, users will need sufficient cooling to prevent the IC's thermal shutdown.

Jumper

Never modified a jumper before?

Check out our Jumper Pads and PCB Traces tutorial for a quick introduction!

There is a jumper on the back of the board that can be used to easily modify a hardware connection on the board. (Not available on baby buck regulator board.)

- PWR - This jumper can be used to remove power to the

PWRLED.

The LED jumper on the back of the 5V Buck Regulator (AP63357DV).

Hardware Assembly

Danger: These boards can get extremely HOT

Please handle these boards with the utmost caution. Users can easily burn themselves when the board outputs anything over 2A.

Headers

New to soldering?

If you have never soldered before or need a quick refresher, check out our How to Solder: Through-Hole Soldering guide.

The pins for the SparkFun 5V Buck Regulator Breakout boards are broken out to 0.1"-spaced pins on the outer edges of the board. When selecting headers, be sure you are aware of the functionality and board orientation required.

Soldering headers to the 5V Buck Regulator (AP63357DV). |

Soldering headers to the 5V Baby Buck Regulator (AP63357DV). |

Hookup Wire

New to soldering?

If you have never soldered before or need a quick refresher, check out our How to Solder: Through-Hole Soldering guide.

Users can also solder their wire connections directly to the pins of the SparkFun 5V Buck Regulator Breakout boards. When planning out the connections, be sure you are aware of the functionality required.

Danger

With higher current applications, users should ensure the wires can handle the current load. (i.e. A 32AWG wire probably won't be able to handle 3.5A)

Soldering wires to the 5V Buck Regulator (AP63357DV). |

Soldering wires to the 5V Baby Buck Regulator (AP63357DV). |

Alternative Connections

Buck Regulator (only)

The following features are only available on the Buck Regulator and are not available on BabyBuck Regulator.

New to soldering?

If you have never soldered before or need a quick refresher, check out our How to Solder: Through-Hole Soldering guide.

To add a barrel jack connector to their board, users will need to solder it to the provided plated through hole slots.

A screw terminal is a great non-permanent solution, to connect the board. To use the screw terminals, simply insert the correct wires into the screw terminal opening and tighten the screw with a small flathead screwdriver for a firm connection.

Heat Sink

Tip

With larger heat sinks, we recommend a test fit and attaching it last to avoid conflicts with other parts of the board. For example, the heat sink could block the PTH pins/slots or access to the jumper pad.

To attach a heat sink to the board, users will also need a piece of thermal tape. We recommend the following procedure:

-

Cut out a piece of thermal tape to fit the bottom of the heat sink.

Tip

Covering the entire bottom of the heat sink can insulate the electrical contacts on the board from shorting.

- For a perfect fit, users can place the heat sink over the tape and trace the outline to cut with scissors.

- For a perfect fit, users can also place the heat sink over the tape and cut the outline with a hobby knife.

-

Place the piece of thermal tape on the bottom of the heat sink.

Tip

We recommend peeling off just one side of the backing sheet or release liner to place the thermal tape on the heat sink. Users can then peel the other side off when they are ready to place the heat sink on their board.

-

Attach the heat sink to the board.

- Make sure to make any jumper modifications and/or solder any connections before placing the heat sink on the board.

- Make sure to avoid any electrical contact with the sides of the heat sink.

Heat sink attached to the 5V Buck Regulator (AP63357DV). |

Heat sink attached to the 5V Baby Buck Regulator (AP63357DV). |

Troubleshooting Tips

Danger: These boards can get extremely HOT

Please handle these boards with the utmost caution. Users can easily burn themselves when the board outputs anything over 2A.

Need Help?

If you need technical assistance or more information on a product that is not working as you expected, we recommend heading on over to the SparkFun Technical Assistance page for some initial troubleshooting.

If you can't find what you need there, the SparkFun Forums is a great place to search product forums and ask questions.

Account Registration Required

If this is your first visit to our forum, you'll need to create a Forum Account to post questions.

Maximum Current

While the AP6337 is rated up to 3.5A, users may experience thermal limitations towards that maximum.

- Users should reasonably expect to be able to place a maximum 3A load on the boards when using a heat sink and active cooling.

- At the peak load of 3.5A, users will need sufficient cooling to prevent the IC's thermal shutdown.

Note

- Without a heat sink or active cooling, we recommend users not load the boards with more than 1.5A.

- With a heat sink, we have found users can expect to draw up to 2.5A

Connecting Batteries

For lower current applications, users can connect a battery as the power source. However, we would only recommend using the 9V battery products from our catalog.

Warning

Other products such as the coin cell battery holder, 2x18650 battery holder, and any of the 4xAA battery holders could technically work. However, we would advise against them for the following reasons:

- For the coin cell battery holder and any of the 4xAA battery holders (using alkaline batteries), users wouldn't be able to use the full capacity of their batteries.

- The initial total voltage of the batteries would typically be above the nominal 6V and potentially work. However, as the batteries discharged they would eventually cross the 6V UVLO threshold of the buck converter well before they were completely depleted.

- In short, users would maybe be using ~85% of their battery's total capacity at best.

- The 18650 lithium-ion batteries in our catalog don't include a battery protection circuit. With two batteries in series, they would bypass their cutoff voltage (~3.2V). This would permanently damage the batteries and render them useless.

Automobile Batteries

While users could connect a 12V car, motorcycle, marine, etc. battery for higher current applications, users may find this 5V/3A Buck Converter easier to mount and connect.

Bypass the UVLO

Default Configuration

On our boards, the EN pin is used to configure the UVLO threshold. Therefore, the power output from the board is enabled by default.

On the 5V Buck Regulator, users can short/jumper the VIN and EN pins. This will bypass the 6V undervoltage lockout setting and allow users to provide a lower input voltage. However, it should be noted that because this is a step-down converter, the output voltage will then be limited to the voltage of the power supply and may not be 5V (if the input voltage ≤5V).

Jumpering the EN and VIN pins on the 5V Buck Regulator to bypass the UVLO to use an input voltage below 6V.

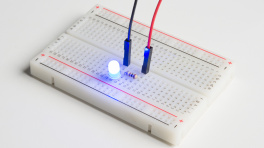

Test Setup

For users who would like to test their buck regulators, this page demonstrates a simple load test on the 5V buck regulator board.

Note

Users who wish to test the maximum parameters of their board will need to consider the thermal and current limitations of the hardware. At minimum:

- A professional/benchtop DC electric load tester should be used instead of the variable load kit.

- Active cooling should be provided to the buck regulator.

Required Hardware

To test the buck regulator boards, users will need the following hardware:

- DC Electric Load Tester

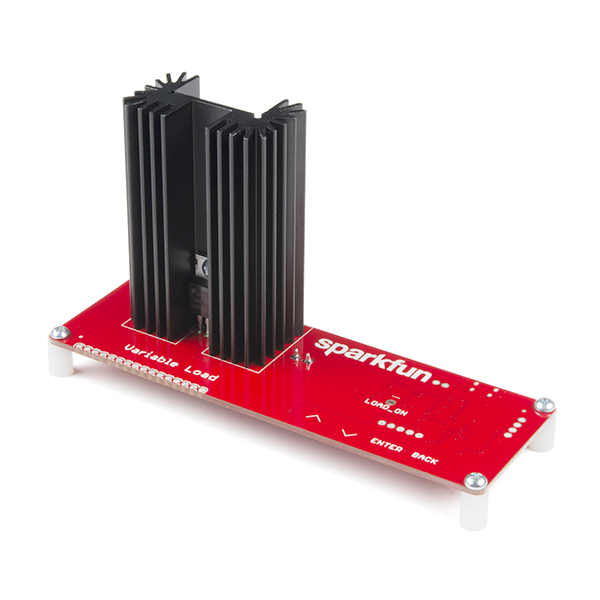

- We are using the SparkFun Variable Load Kit

- Power Supply

- Use a benchtop-style power supply where you can configure the output voltage and see the current draw when loaded.

- We are using the 80W DC Power Supply (retired product)

Power Supply - 80W DC Switching ModeTOL-09291 |

SparkFun Variable Load KitKIT-14449 |

Hardware Setup

For this test, the hardware was setup up as follows:

- Power was supplied to the buck regulator through the soldered barrel jack.

- The output power from the buck regulator was connected to the variable load kit, through the screw terminal.

- Power was enabled using a jumper on the headers, soldered to the

VINandENPTH pins. - No heat sink was attached to the buck regulator.

Test

To perform the test, the power supply was set to provide 6.08V at up to 4A. Meanwhile, the SparkFun variable load kit was configured to draw 1A(1).

- For current draws over 1.5A, users should include a heat sink; and active cooling for loads over 2.5A.

Setup for a basic load test on the 5V Buck Regulator (AP63357DV).

Although it is a little hard to see in the picture, the power supply is providing 6.08V with a 928mA current draw to the buck regulator. The variable load kit is drawing 1A with the 5.11V output voltage from the buck regulator.

Resources:

Product Resources

-

Composite (Both Boards)

- Product Category

- Board Dimensions

- AP63357 Datasheet

- Design Files:

-

Buck Regulator Breakout - 5V (AP63357)

-

BabyBuck Regulator Breakout - 5V (AP63357)

Additional Resources

🏭 Manufacturer's Resources

Diodes Incorporated also provides great resources for the AP63357 Buck Regulator: